The most frequently asked issues about biomass and how it fits into your project are addressed in this article. Visit our main Biomass Boiler page for additional details on the benefits and various types of biomass boiler.

What is biomass?

The term “biomass” is an academic one that frequently confounds laymen. In actuality, “biomass” is shorthand for “biological mass.” It is a form of fuel obtained from any biological source (plant or animal). One sort of biomass heating, among many others, is wood fuel.

In the context of sustainable heating, the term “biomass” refers to solid biomass fuels that may be burned in our biomass boilers, such as wood (logs, chips, and pellets), grain, or miscanthus.

How different is a biomass boiler to a fossil fuel boiler?

Your current fossil fuel boiler is easily replaced by a biomass boiler, which is then connected to your current heating system, whether it be radiators, underfloor heating, or warm air heating.

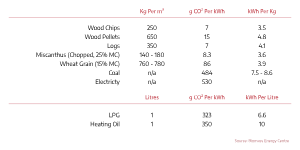

Biomass v fossil fuels:

Compared to fossil fuels, biomass has three key advantages:

It may be considerably less expensive. When existing wood supplies are contracted chipped, for instance, savings of 80% against total oil can be realised.

It can produce sizeable yearly payments for heat produced and utilised under programmes like the Renewable Heat Incentive.

Because it releases the same amount of CO2 when burned as it did when it was alive, biomass is carbon neutral. As a result, it is environmentally friendly, abundant, and decreases emissions by up to 96%, according to the Biomass Energy Centre.

How does a biomass boiler work?

Fuel handling and delivery

You shouldn’t notice any differences in fuel handling because the majority of contemporary commercial biomass boilers are mechanically supplied, much like an oil or LPG boiler. This means that you shouldn’t handle fuel by hand!

Delivery trucks, which are often blown or gravity fed, automatically feed wood pellets into fuel storage facilities.Typically, wood chips are tossed via a retractable roof or fed into a fuel store through an access hatch on the store’s side. An alternative is to chip the wood right into a fuel depot, where it is kept dry and available for use.

Fuel storage

Custom-built fuel storage facilities, building conversion projects and pre-fitted shipping containers are all options. The store should be constructed so that just three or four fills are necessary per year. The fuel storage area should be kept dry and clear of pollutants and foreign objects including stones, animal remains, metals, coatings, and preservatives.

An agitator, which consists of a revolving disc with spring arms, is used to stir wood chips. The fuel is then poured into an auger, a massive corkscrew that neatly transports the fuel from the store to the boiler.Due to the free-flowing nature of wood pellets (pourable grain, chopped, or pelleted Miscanthus), the fuel depots are constructed at an angle and fed into the boiler. The fuel must be manually fed into the boiler when utilising logs.

Gasification

A stove or open fire operate slightly differently than a biomass boiler. ‘Gasification’ is the term used to describe the process. This indicates that the fuel is burned to release gases at a temperature of 600 C. The hot gases are subsequently re-burned, giving gasification its name, and temperatures of 1,200 C are produced.

Buffer tanks and thermal stores

The hot water that is supplied throughout the central heating system is stored in buffer tanks, also known as thermal storage. This results in a much more efficient heating system because the biomass boiler’s purpose is to raise tank temperatures rather than generating heat from scratch each time.

Fertiliser by-product

The majority of the contemporary biomass boilers we sell produce 0.5–1% ash relative to the amount of fuel burned. Thus, only every 6 to 8 weeks do the enormous ash bins need to be emptied. Due to its high nitrate content, wood fuel ash is a fantastic fertiliser.

Saving money and the environment

In addition to lowering CO2 emissions and saving the environment, using biomass to heat your home can also lower fuel costs and, if you qualify for the government’s RHI programme, qualify for compensation based on the amount of heat produced and used.

Fuel prices:

Wood pellets might reduce your fuel expenditures by 20–40%.

Wood chips: You can save your fuel expenditures by about 50%.

Your own chip You might save your fuel bills by up to 80%.

Renewable Heat Incentive (RHI)

Owners of biomass boilers are compensated under the RHI, a government programme, for the heat they produce and consume. In November 2011, the Renewable Heat Incentive (RHI) for business use was introduced. In April 2014, the second phase of the programme, which focuses on residential properties, was introduced.

Its goal is to enable the UK to meet its legally mandated 2020 carbon reduction targets of 20% by expanding the deployment of renewable heat sources, particularly biomass boiler heating systems.

The programme operates by providing owners of biomass boiler heating systems with a financial incentive to switch from fossil fuels to renewable sources of heating.

Commercial RHI payments are computed using quarterly metre readings submitted to Ofgem over a 20-year period and based on heat usage measured in kWh. Domestic RHI payments are determined over a seven-year period based on the ‘deemed’ or approximate heat use indicated in an EPC.

Commercial RHI examples

When compared to fossil fuels, a big rural estate with seven distinct buildings that uses a 100kW biomass boiler to chip their own wood may save up to 80% on fuel expenses and gain roughly £11,000 per year for 20 years, index tied to inflation.

Domestic RHI examples

With an installed cost of £23,000 (for wood pellets) or £27,000 (for logs), a 40kW biomass boiler that heats a six-bedroom house with an EPC rating of 52,560 kWh per year would earn £6,412 per year over seven years and pay for itself in about three to four years.

We hope the information above is helpful, but do get in touch with us if you want to talk about any other aspects of your biomass boiler project. You can also leave your information and we’ll get back to you.